- Lun–Ven 9h00–18h00

- +371 20385777

Instructions for use

1 Use of roundslings and webbing slings (sling) in adverse conditions or hazardous applications

1.1 The material from which slings are manufactured has selective resistance to chemicals. Polyester (PES) is resistant to most mineral acids but is damaged by alkalis; Solutions of acids or alkalis which are harmless can become sufficiently concentrated by evaporation to cause damage. Contaminated slings should be taken out of service at once, soaked in cold water, dried naturally and referred to a competent person for examination. Slings with grade 8 fittings and multi-leg slings with grade 8 master links should not be used in acidic conditions. Contact with acids or acidic fumes causes hydrogen embrittlement to grade 8 materials. If exposure to chemicals is likely, the manufacturer or supplier should be consulted.

1.2 Slings are suitable for use and storage in the following temperature ranges: a) polyester: -40°C to 100°C. At low temperatures ice formation will take place if moisture is present. This may act as a cutting agent and an abrasive causing internal damage to the sling. Further, ice will lessen the flexibility of the sling, in extreme cases rendering it unserviceable for use. These ranges vary in a chemical environment, in which case the advice of the manufacturer or supplier should be sought. Limited indirect ambient heating, within these ranges, is acceptable for drying.

1.3 The man-made fibres from which the slings is produced are susceptible to degradation if exposed to ultra-violet radiation. Slings should not be stored in direct sunlight or sources of ultra violet radiation.

2 Inspection of roundslings and webbing slings in service

2.1 Before first use of the sling it should be ensured that: a) the sling corresponds precisely to that specified on the order; b) the manufacturer’s certificate is to hand; c) the identification and WLL marked on the sling correspond with the information on the certificate.

2.2 Before each use, the sling should be inspected for defects and to ensure that the identification and specification are correct. A sling that is unidentified or defective should never be used, but should be referred to a competent person for examination. EC-Declaration is available.

2.3 During the period of use, frequent checks should be made for defects or damage, including damage concealed by soiling, which might affect the continued safe use of the sling. These checks should extend to any fittings and lifting accessories used in association with the sling. If any doubt exists as to the fitness for use, or if any of the required markings have been lost or become illegible, the sling should be removed from service for examination by a competent person. Any damage evident in the cover (roundsling) indicates potential damage to the loadbearing core. The following are examples of defects or damage likely to affect the fitness of slings for continued safe use:

a) Surface chafe. In normal use, some chafing will occur to the surface fibres of the cover (roundsling). This is normal and has little effect. Any substantial chafe, particularly localized, should be viewed critically. Local abrasion, as distinct from general wear, can be caused by sharp edges whilst the sling is under tension, and can lead to the cover (roundsling) becoming cut, or/and cause serious loss of strength.

b) Roundsling: Cuts. Cross or longitudinal cuts in the cover, or any damage to the stitching, raise serious doubts as to the integrity of the core. Webbing sling: Cross or longitudinal cuts, cuts or chafe damage to selvedges, cuts to stitching or eyes.

c) Exposed core (roundsling).

d) Chemical attack. Chemical attack results in local weakening and softening of the material. This is indicated by flaking of the cover/surface which may be plucked or rubbed off. Any signs of chemical attack to the cover (roundsling) raise serious doubts as to the integrity of the core (roundsling).

e) Heat or friction damage. This is indicated by the fibres of the cover/ surface material taking on a glazed appearance and in extreme cases, fusion of the fibres can occur, indicating a weakening of the core (roundsling).

f) Damaged or deformed fittings.

3 Correct selection and use of roundslings and webbing slings

3.1 When selecting and specifying slings, the following must be considered:

3.1.1 Slings must have the required working load limit, taking into account the mode of use and the nature of the load to be lifted. Proper selection of a sling is influenced by the size, shape and weight of the load, together with the intended method of use, the working environment and the nature of the load. The selected sling should be strong enough as well as

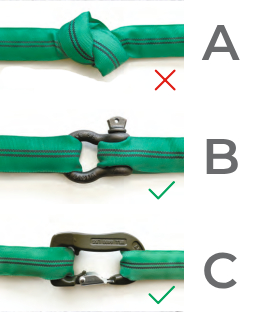

3.1.2 Have the correct length for the mode of use. Slings should preferably consist of one length or be extended with the right fittings. Knots and loops in slings - see picture A - are not permitted. The termination of the sling should also be considered i.e. whether fittings or soft eyes are required (see picture B and C).

3.1.3 If more than one sling is used to lift a load, these slings should be identical. The material from which the slings is made should not be affected adversely by the environment or the load.

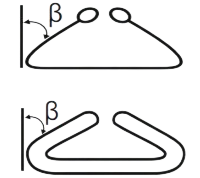

3.2 Webbing slings: When using slings with soft eyes, the minimum eye length for a sling for use with a hook should be not less than 3,5 times the maximum thickness of the hook and in any event the angle formed in the eye of the sling should not exceed 20°. When connecting a sling with soft eyes to a lifting appliance, the part of the lifting appliance which bears on the sling should be essentially straight, unless the bearing width of the sling is not more than 75 mm in which case the radius of curvature of the lifting appliance attachment should be at least 0,75 times the bearing width of the sling. Figure 1 illustrates the problem of accommodating webbing on a hook of radius less than 0,75 times the bearing width of the sling. Wide webbings may be affected by the radius of the inside of the hook as a result of the curvature of the hook preventing uniform loading across the width of the webbing.

Figure 1 inadequate accommodation of a webbing eye on a hook of too small radius.

3.3 Slings should not be overloaded: the correct mode factor should be used (see table)

| 1-leg | U-lift | Lace d | 1-leg angle | 2-leg sling | 3-,4-leg sling | ||||

|---|---|---|---|---|---|---|---|---|---|

| Angle of inclination |

|

|

|

|

|

|

|||

| 0°-45° | 45°-60° | 0°-45° | 45°-60° | 0°-45° | 45°-60° | ||||

| Load factor | 1 | 2 | 0,8 | 1,4 | 1 | 1,4 | 1 | 2,1 | 1,5 |

| Colour | WLL ton | ||||||||

| Purple | 1,0 | 2,0 | 0,8 | 1,4 | 1,0 | 1,4 | 1,0 | 2,1 | 1,5 |

| Green | 2,0 | 4,0 | 1,6 | 2,8 | 2,0 | 2,8 | 2,0 | 4,2 | 3,0 |

| Yellow | 3,0 | 6,0 | 2,4 | 4,2 | 3,0 | 4,2 | 3,0 | 6,3 | 4,5 |

| Grey | 4,0 | 8,0 | 3,2 | 5,6 | 4,0 | 5,6 | 4,0 | 8,4 | 6,0 |

| Red | 5,0 | 10,0 | 4,0 | 7,0 | 5,0 | 7,0 | 5,0 | 10,5 | 7,5 |

| Brown | 6,0 | 12,0 | 4,8 | 8,4 | 6,0 | 8,4 | 6,0 | 12,6 | 9,0 |

| Blue | 8,0 | 16,0 | 6,4 | 11,2 | 8,0 | 11,2 | 8,0 | 16,8 | 12,0 |

| Orange | 10,0 | 20,0 | 8,0 | 14,0 | 10,0 | 14,0 | 10,0 | 21,0 | 15,0 |

Working load limits for some modes may be given on the label. In the case of multi-leg slings the maximum angle to the vertical should not be exceeded.

3.4 Good slinging practices should be followed: the slinging, lifting and lowering operations should be planned before commencing the lift.

3.5 Slings should be correctly positioned and attached to the load in a safe manner. Slings should be placed on the load such that they are able to adopt the flattened form and the loading is uniform across their width. They should never be knotted or twisted. Damage to labels should be prevented by keeping them away from the load, the hook and the angle of choke.

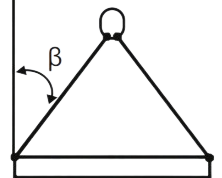

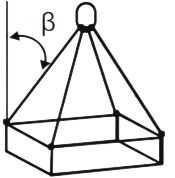

3.6 In the case of multi-leg slings, the WLL values have been determined on the basis that the loading of the sling assembly is symmetrical. This means that when a load is lifted the sling legs are symmetrically disposed in plan and subtended at the same angle to the vertical. In the case of 3 leg slings, if the legs are not symmetrically disposed in plan the greatest tension is in the leg where the sum of the plan angles to the adjacent legs is greatest. The same effect occurs in 4 leg slings except that the rigidity of the load should also be taken into account.

3.7 Slings should be protected from edges, friction and abrasion, whether from the load or the lifting appliance. Where protection against damage from edges and/or abrasion is supplied as part of the sling, this should be correctly positioned. It may be necessary to supplement this with additional protection.

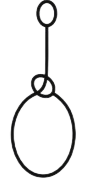

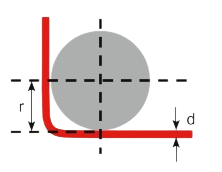

Definition of a sharp edge:

Radius r (edge) < thickness d of the lifting gear.

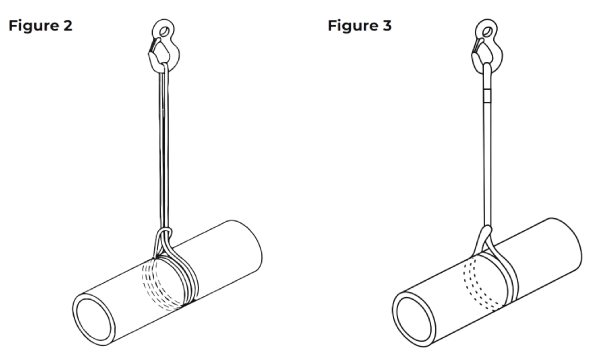

3.8 The load should be secured by the sling(s) in such a manner that it cannot topple or fall out of the sling(s) during the lift. Sling(s) should be arranged so that the point of lift is directly above the centre of gravity and the load is balanced and stable. Movement of the sling over the lifting point is possible if the centre of gravity of the load is not below the lifting point. When using basket hitch, the load should be secure since there is no gripping action as with choke hitch and the sling can roll through the lifting point. For slings which are used in pairs, the use of a spreader is recommended so that the sling legs hang as vertically as possible and to ensure that the load is equally divided between the legs. When a sling is used in choke hitch, it should be positioned so as to allow the natural (120°) angle to form and avoid heat being generated by friction. A sling should never be forced into position nor an attempt made to tighten the bite. The correct method of securing a load in a double choke hitch is illustrated in figure 2 (roundsling) and 3 (webbing slings) double choke hitch provides greater security and helps to prevent the load sliding through the sling.

3.9 Care should be taken to ensure the safety of personnel during the lift. Persons in the danger area should be warned that the operation is to take place and, if necessary, evacuated from the immediate area. Hands and other parts of the body should be kept away from the sling to prevent injury as the slack is taken up. The work with lifting devices and equipment’s must be planned, organized and executed in order to prevent hazardous situations. In accordance with national statutory regulations lifting devices and equipment’s must only be used by someone well familiar with the work and having theoretical and practical knowledge of safe use. Apart from the instruction manual we refer to existing national regulations on each work place.

3.10 A trial lift should be made. The slack should be taken up until the sling is taut. The load should be raised slightly and a check made that it is secure and assumes the position intended. This is especially important with basket or other loose hitches where friction retains the load. If the load tends to tilt, it should be lowered and attachments re-positioned. The trial lift should be repeated until the stability of the load is ensured.

3.11 Care should be taken when making the lift to ensure that the load is controlled, e.g. to prevent accidental rotation or collision with other objects. Snatch or shock loading should be avoided as this will increase the forces acting on the sling. A load in the sling or the sling itself should not be dragged over the ground or rough surfaces.

3.12 The load should be lowered in an equally controlled manner as when lifted. Trapping the sling when lowering the load should be avoided. The load should not rest on the sling, if this could cause damage and pulling the sling from beneath the load when the load is resting on it should not be attempted.

3.13 On completion of the lifting operation the sling should be returned to proper storage. When not in use, slings should be stored in clean, dry and well ventilated conditions, at ambient temperature and on a rack, away from any heat sources, contact with chemicals, fumes, corrodible surfaces, direct sunlight or other sources of ultra-violet radiation.

3.14 Prior to placing in storage, slings should be inspected for any damage which may have occurred during use. Slings should never be returned damaged to storage.

3.15 Where lifting slings have come into contact with acids and/or alkalis, dilution with water or neutralization with suitable media is recommended prior to storage. Depending on the material of the lifting sling and on the chemicals referred to in 1, 1.1, it may be necessary in some cases to request from the supplier additional recommendations on the cleaning procedure to be followed after the sling has been used in the presence of chemicals.

3.16 Slings which have become wet in use, or as the result of cleaning, should be hung up and allowed to dry naturally, not near a heat source.

4 Examination and repair

Examination periods should be determined by a competent person, taking into account the application, environment, frequency of use and similar matters, but in any event, slings should be visually examined at least annually by a competent person to establish their fitness for continued use. Records of such examinations should be maintained. Damaged slings should be withdrawn from service. Never attempt to carry out repairs to the slings yourself.

5 Information

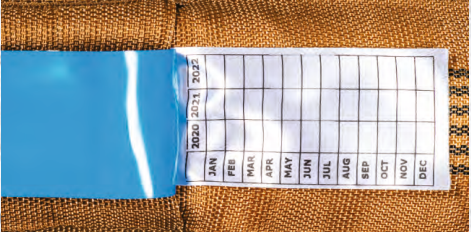

We recommend a maximum life span of 10 years, effective from the date of production. This may be extended, but depends on a more detailed examination. Before first use: Mark up the date for first use by year and month the example shown.

End of use/Disposal

Lifting slings shall always be sorted / scrapped as polyester scrap. Main material is polyester.

Disclaimer

We reserve the right to modify product design, materials, specifications or instructions without prior notice and without obligation to others. If the product is modified in any way, or if it is combined with a non-compatible product/component, we take no responsibility for the consequences in regard to the safety of the product.

Declaration of conformity

SIA AVOCET LIFTING

A.Degalava iela 50,

LV-1035 Riga,

LATVIA

hereby declares that roundslings and textile slings as described above is in compliance with EC Machinery Directive 2006/42/EC and amendments & EN 1492-1, -2.

Production en Lettonie

Depuis 2011, AVOCET LIFTING exploite 3 000 m² d'installations à Riga, couvrant le tissage, la teinture, les tests et la certification, ce qui nous permet de contrôler à 100 % notre qualité du début à la fin.

Livraisons internationales

Nous expédions directement depuis la Lettonie vers de nombreux pays de l’UE, notamment la Scandinavie et le Royaume-Uni.

Qualité

& Innovation

Nos spécialistes ont plus de 15 ans d'expérience. Nous disposons d'une machine d'essai Sahm Splice de classe 1 de 100 tonnes à la pointe de la technologie, qui nous permet d'obtenir un certificat d'essai professionnel et de contrôler entièrement la qualité de nos produits.